*We are still populating our archive. Below are a list of the most recent projects we have completed.

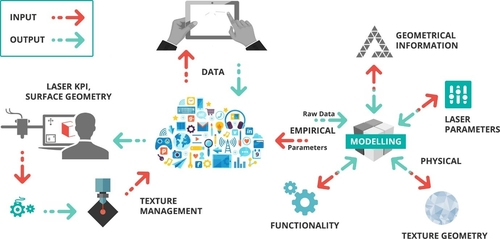

SHARK – Industrialising laser functional texturing

Point of contact: Duncan Hand (D.P.hand@hw.ac.uk)SHARK is a collaboration of research organisations, technology providers and end-users coming together to industrialise laser functional texturing. This market leading consortium covers the full value chain for laser surface engineering and has access to global markets.

SHARK aims to industrialise laser functional texturing by boosting the productivity, cost effectiveness and flexibility of the process.

Our objectives are:

• To significantly increase productivity and cost effectiveness by reducing time required for laser processing, inspection and product design and introduction;

• To develop a highly robust laser texturing system capable of producing different surface textures for specific functionalities, supported by modelling tool development

and in-line inspection tools;

• To develop a scalable integrated digital platform with high data security;

• To demonstrate and commercial exploit laser surface texturing in the tooling, food and drink, medical and power generation sectors.

We are reducing the complexity and unknowns in the functional texturing process by developing a fully digitised knowledge management platform and an advanced end-user

interface to enable industrialisation of the process.

The project will deliver:

• Cost savings: The capability to deliver surface functionalities into real products for less than 10% of the cost of the conventional part.

• Improved product performance: More than 20% improvement in product performance based on the surface functionalities deployed

• Faster product development

• A strengthened global position for European manufacturing

Duncan Hand, Wojciech Gora, Juan Pedro Godoy Vilar, Jonathan Shephard, Robert Maier (list only include people at Heriot Watt University and is not exhaustive)

Duncan Hand, Wojciech Gora, Juan Pedro Godoy Vilar, Jonathan Shephard, Robert Maier (list only include people at Heriot Watt University and is not exhaustive)

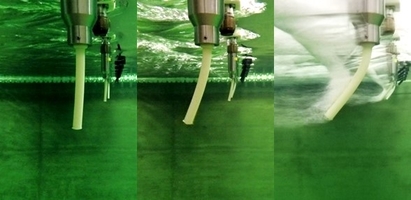

LAkHsMI - Sensors for large hydrodyanmic imaging of the ocean floor

Point of contact: Bill MacPherson (W.N.MacPherson@hw.ac.uk)The project, funded by EU H2020, is aimed at developing a new bio-inspired technology to make continuous cost-effective measurements of the near-field, large-scale hydrodynamic situation, for environmental monitoring in cabled ocean observatories, marine renewable energy and port/harbour security.

The LAkHsMi approach is inspired by the biophysics of the of fish lateral line organ, by far the most sophisticated, reliable, versatile and robust mechano-sensory organ for hydrodynamic

sensing known. The project aims at building macroscopic sensors arrays (scalable to kilometres long) for hydrodynamic visualisation and large-scale oceanography. This will help in enhancing

the understanding of complex sub-surface flow conditions. To date surprisingly little is known about these flows, their dynamics and the long-term effects on the environment since no suitable

metrology is available for continuous and long term study. The Ocean’s surface layers are sampled with enough horizontal resolution but information about the water column is presently poor

and measurements contain significant errors due to under sampling. The project aims at providing the answers to these challenges through the development of a new technology for benthic marine

observations with optical underwater measuring probes based on multiplexed fiber optic sensors. These optical sensors arrays can measure the magnitude and direction of the flow and the

temperature of the ocean floor in lateral and temporal scales not considered to date by existing observation techniques. They will be able to form the basis for a form of hydrodynamic

imaging that will make a completely new sensing modality available.

Bill MacPherson, Adrian Dzipalski, Robert Maier

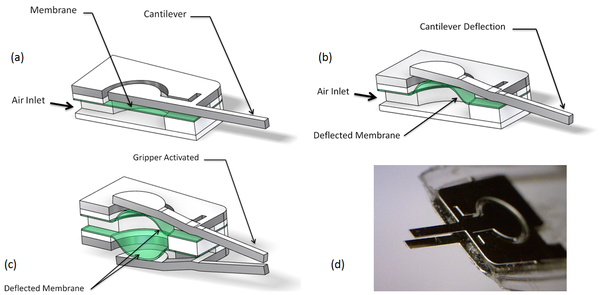

DynoClaw: A dynamic palpation device with two points of tissue contact

Point of contact: Prof Duncan Hand (D.P.Hand@hw.ac.uk)Cancerous tissue has a different stiffness to healthy tissue and so mechanical testing can be successfully used to identify cancerous regions for subsequent treatment. This project seeks to develop an endoscopically deployable miniature mechanical device for stiffness measurement in order to detect soft tissue cancer.

Cancerous tissue has a different stiffness to healthy tissue and so mechanical testing can be successfully used to identify cancerous regions for subsequent treatment. This approach

has been used as the basis of a palpation device for prostate cancer diagnosis currently undergoing clinical trials and commercialisation. In this project we are working to develop

a similar device that can be deployed through the working channel of an endoscope, for application to minimally invasive diagnosis of other cancers. Our contribution is to develop

the laser-based manufacturing processes and overall process chain (including bonding of multiple materials) to enable the fabrication of a device with suitable performance but no

more than 3.2 mm outer diameter.

Bob Reuben, Yuhang Chen, Duncan Hand, Wojciech Gora, Michael Crichton, Sufi Erden, Duncan Hand, Jon Shephard, Alan McNeill, Hugh Paterson, Colin Noble

Bob Reuben, Yuhang Chen, Duncan Hand, Wojciech Gora, Michael Crichton, Sufi Erden, Duncan Hand, Jon Shephard, Alan McNeill, Hugh Paterson, Colin Noble

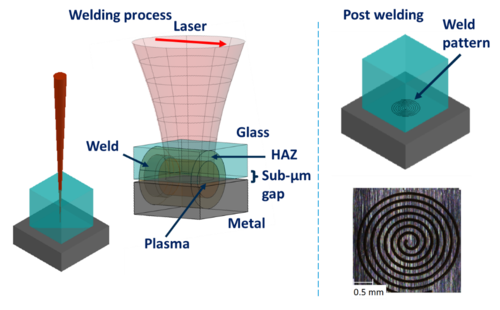

(UltraWELD) ULTRAfast laser WELDing of highly dissimilar materials – development of a truly industrial process

Point of contact: Duncan Hand (D.P.Hand@hw.ac.uk)The UltraWELD project concerns use of ultrashort pulsed lasers to weld optical materials such as glass, either to optical materials or to structural materials (e.g. metals). Working with a range of industrial partners we are developing industry-ready recipes for welding highly dissimilar materials and ultrathin flexible glass. We are translating this technology to industrial application via the development of a custom laser bonding prototype machine.

Most products contain a mixture of materials and joining these together can in some cases be challenging. For example, metal:glass assemblies are used in a number of manufactured products,

including complex electro optics devices for defence/aerospace applications etc. Typically, an indirect bonding technique is used, based around an intermediate interlayer, e.g. adhesive,

solder or frit. However, these techniques have limitations, in particular with regards to unwanted contamination of other surfaces. Also, precise and reproducible positioning can be

difficult, and adhesives can creep over time. In UltraWELD we are developing a direct bonding (welding) process using an ultrashort pulsed (picosecond) laser for highly dissimilar materials,

see Figure 1. Also, laser welding of two 100 µm thick flexible glass sheets for OLED encapsulation is being evaluated as an alternative to current polymer sealing techniques, Figure 2.

We are working with project partner Oxford Lasers to translate this technology to industrial application via the development of a custom laser bonding prototype machine.

P.O.Morawska, R.M.Carter, D.M.J. Esser, D.P. Hand, Glass Technology Services (GTS), Oxford Lasers, Centre for Process Innovation (CPI), Coherent, Gooch&Housego, Leonardo

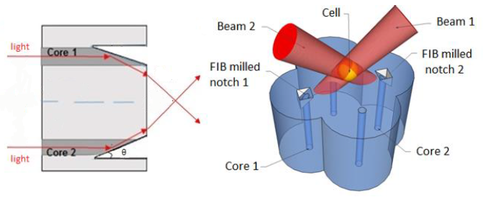

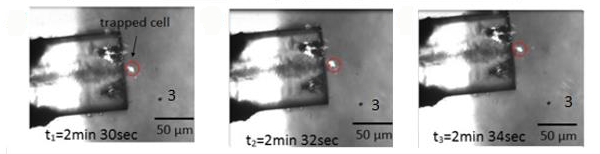

Novel optical fibres for enhanced optical trapping

Point of contact: Bill MacPherson (W.N.MacPherson@hw.ac.uk)In this project we investigate the potential application of micro-optics on the end of a multicore fibre for the development of single-fibre optical cell trap. We have demonstrated this approach in imaging and spectroscopic applications to cell biology.

Optical manipulation (or optical trapping or tweezing) enables particles from tens of nanometers to tens of microns in diameter to be picked up and moved using only light.

This project has developed techniques that have allowed us to develop an optical fibre trap using multicore optical fibres in order to hold, and controllably move, individual

micro and nanoscopic particles in three dimensions. This fibre trap has several distinct advantages: i) it allows the operator to control trapping of individual particles

independently, enabling the interactions between single particles of different species to be examined and ii) does not depend on a powerful microscope objective lens to

perform the trapping. The trapping probes can be used with conventional microscope instrumentation without the need to specially modify the optical imaging system.

Focused ion beam fabrication has been used to create our custom micro-optics onto the end of optical fibres that uniquely enable three dimensional optical trapping of a single

particle at the output of a single fibre. This project builds on our existing experience in optical trapping, fibre optics, microfabrication using focussed ion beam milling and

laser machining. The project has a wide range of applications in nanotoxicology and cell biology.

Georgia Anastasiadi, Bill MacPherson, Lynn Paterson (Institute of Biological Chemistry, Biophysics and Bioengineering, HWU)

Georgia Anastasiadi, Bill MacPherson, Lynn Paterson (Institute of Biological Chemistry, Biophysics and Bioengineering, HWU)

Metasurfaces A-La-Carte using phase change materials

Point of contact: Duncan Hand (D.P.hand@hw.ac.uk)The project aims to deliver metasurfaces with a switchable range of responses to RF signals (e.g. radar). A new technique is being investigated based on optically-switchable material phases to provide a localised change from insulating to conducting. This approach is being tested for GHz applications.

The project demonstrates a proof of concept of an optically actuated dynamically reconfigurable metasurface A-La-Carte system for the 5-50 GHz

range applications such as on demand radar cross section manipulation. Usually, typical metasurfaces are limited to one design having one performance characteristic (reduction in the radar

cross section as a specific frequency or reflection of an incident wave at a certain angle). Reconfigurable metasurfaces can have two or more functionalities but require complicated biasing

networks and actuation methods that may limit the design and performance capabilities. In this research a single device is proposed that can perform as many different metasurfaces aided by

a phase changing material acting as an insulator in one state and as a conductor in the other state.

Dimitris Anagnostou, Duncan Hand, George Goussetis, Adrian Dzipalski, Jia Ni, Qassim Abdullahi

Anti-counterfeiting holographic markings for high-value metal products

Point of contact: Duncan Hand (D.P.Hand@hw.ac.uk)In this project we investigate a new laser marking technique that enables the direct generation of bespoke holographic structures on metal surfaces. These structures can be used as hard-to-replicate security markings for protecting high-value metal products against counterfeiting.

The project is focused on the development of a laser-based process for the fast, direct generation of hard-to-replicate, anti-counterfeiting, security markings for various high-value

products, including jewellery, engine parts and luxury watches. These markings are in the form of computer-generated holograms (CGHs), designed using an iterative Fourier transform

algorithm (IFTA) and mapped onto the product surface by using a UV nanosecond pulsed laser. The holograms comprise an array of optically-smooth, sub-micron depth surface deformations

whose size and shape are precisely controlled by the laser. The structures are tamper-proof and resistant to mechanical abrasion, high temperatures, and many chemical substances.

Moreover, the holograms can contain additional security elements, e.g. miniature signatures and identifiers, and can be incorporated into standard marking patterns (e.g. Data Matrices

or QR codes) which makes them invisible to the naked eye.

Krystian Wlodarczyk (HWU), Marcus Ardron (Renishaw), Simone Mazzucato (SISMA), Luca Valisari (SISMA), Federico Iacovella (SISMA), Nick Weston (Renishaw), and Duncan Hand (HWU)